The current situation of China's magnet freeze has significant implications for various industries worldwide, particularly the automotive sector. China is a major supplier of rare earth magnets, which are essential components in the production of electric vehicles and other automotive parts. The freeze on magnet exports from China has led to a shortage of these critical components, affecting the global supply chain.

The impact of this shortage is being felt by Indian automakers, who rely heavily on imports from China. Indian companies are facing challenges in sourcing rare earth magnets, which are used in the production of electric motors, generators, and other automotive components. This shortage has the potential to disrupt the production schedules of Indian automakers, leading to delays and increased costs.

Some of the key effects of the magnet freeze on Indian automakers include:

- Disruption of production schedules due to shortage of rare earth magnets

- Increased costs due to higher prices of imported magnets

- Delays in the launch of new electric vehicle models

- Potential loss of market share due to inability to meet demand

The Indian government has been working to reduce the country's dependence on Chinese imports, particularly in the automotive sector. Efforts are being made to promote domestic production of rare earth magnets and other critical components. However, this will take time, and in the short term, Indian automakers will need to find alternative sources of supply to mitigate the impact of the magnet freeze.

The situation highlights the need for Indian automakers to diversify their supply chains and reduce their dependence on imports from China. This can be achieved by investing in domestic production, partnering with suppliers from other countries, and exploring alternative technologies that do not rely on rare earth magnets. By taking these steps, Indian automakers can reduce their vulnerability to disruptions in the global supply chain and ensure a more stable and sustainable future.

What is China's Magnet Freeze?

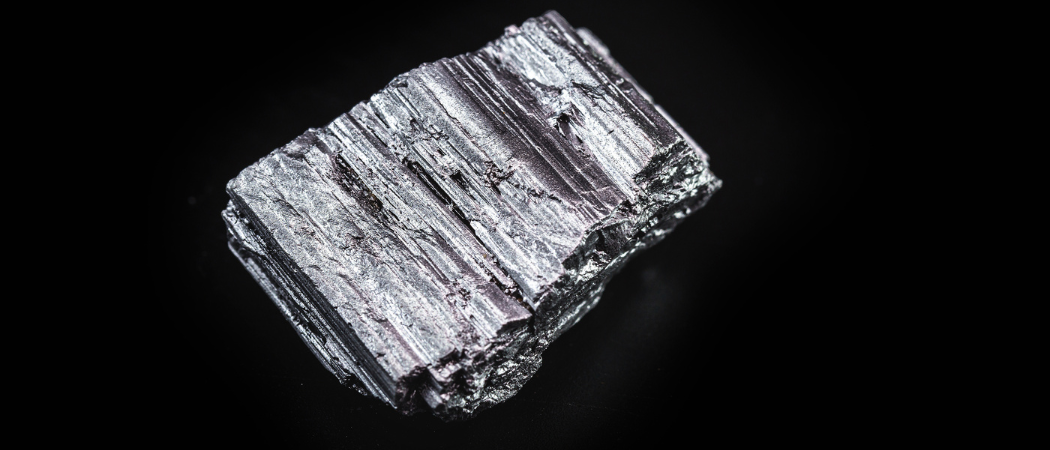

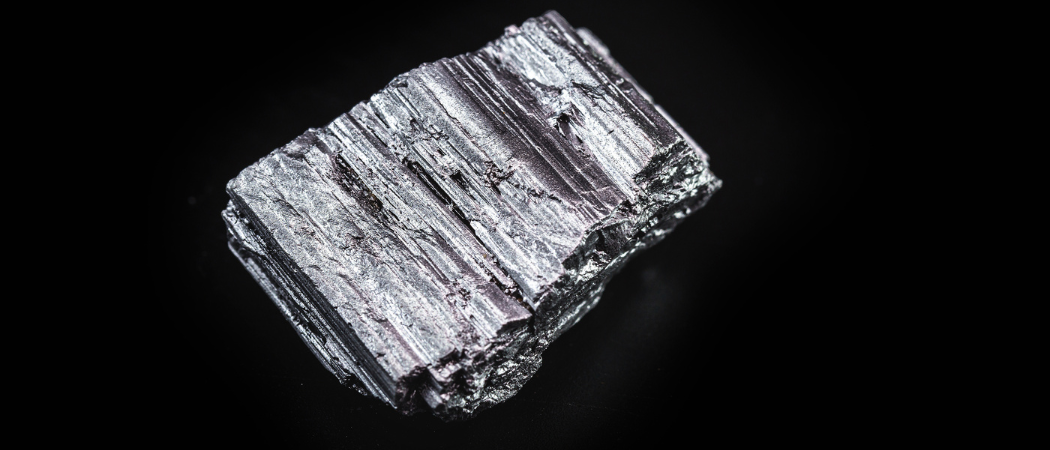

Rare earth magnets are a crucial component in the automotive industry, playing a vital role in the production of electric vehicles, hybrid cars, and other advanced technologies. These magnets are made from rare earth elements, such as neodymium and dysprosium, which are abundant in China. The unique properties of rare earth magnets, including their high magnetic strength and resistance to demagnetization, make them an essential material for the manufacture of electric motors, generators, and other automotive components.

The importance of rare earth magnets in the automotive industry cannot be overstated. They are used in a wide range of applications, including:

- Electric vehicle motors and generators

- Hybrid car systems

- Regenerative braking systems

- Advanced driver-assistance systems (ADAS)

The reliance on rare earth magnets has created a significant demand for these materials, with China being the largest supplier.

A recent development has sent shockwaves through the automotive industry: China's freeze on magnet exports. This freeze has been caused by a combination of factors, including trade tensions, environmental concerns, and China's efforts to consolidate its rare earth industry. The Chinese government has implemented policies to restrict the export of rare earth magnets, citing concerns over the environmental impact of mining and processing these materials.

The freeze on magnet exports from China has significant implications for the automotive industry, particularly for companies that rely heavily on these materials. The shortage of rare earth magnets has led to increased costs and supply chain disruptions, affecting the production of electric vehicles and other advanced technologies. As the industry struggles to adapt to this new reality, manufacturers are being forced to explore alternative sources of rare earth magnets and develop new technologies that can reduce their dependence on these materials.

The causes of China's magnet freeze are complex and multifaceted. Some of the key factors include:

- Trade tensions between China and other countries

- Environmental concerns over the mining and processing of rare earth materials

- China's efforts to consolidate its rare earth industry and reduce exports

- Increased demand for rare earth magnets from the automotive and other industries

As the situation continues to evolve, it remains to be seen how the automotive industry will respond to the challenges posed by China's magnet freeze. One thing is certain, however: the industry will need to adapt and innovate in order to overcome the shortages and supply chain disruptions caused by this freeze.

Impact on Indian Automakers

The Indian automotive industry is facing a significant challenge due to the magnet freeze, which is impacting production and supply chains. The shortage of magnets, a crucial component in the manufacturing of vehicles, has led to a slowdown in production for many Indian car manufacturers. This has resulted in a ripple effect, affecting not only the companies but also the entire ecosystem of suppliers, dealers, and customers.

The magnet freeze has disrupted the supply chain, causing delays and shortages of vital components. Indian car manufacturers rely heavily on imports of magnets from countries like China, which has been affected by the freeze. This has led to a shortage of magnets, forcing companies to either reduce production or stop production altogether. As a result, the companies are facing significant losses, and the industry as a whole is experiencing a decline in sales and revenue.

Some Indian companies are already facing difficulties due to the freeze. For example:

- Tata Motors has reported a significant decline in production due to the shortage of magnets, affecting its popular models like the Tata Nexon and Tata Harrier.

- Mahindra & Mahindra has also been impacted, with the company facing challenges in meeting the demand for its best-selling models like the Mahindra XUV700 and Mahindra Thar.

- Maruti Suzuki, the largest car manufacturer in India, has also been affected, with the company reporting a decline in production due to the magnet shortage.

These companies are working closely with their suppliers to find alternative sources of magnets, but the situation remains challenging.

The impact of the magnet freeze on Indian car manufacturers is not limited to production alone. The shortage of magnets is also affecting the companies' ability to meet customer demand, leading to delays and cancellations of orders. This has resulted in a loss of customer trust and loyalty, which can have long-term consequences for the companies. The industry is hoping for a resolution to the magnet shortage soon, but until then, the challenges will continue to mount.

Alternative Sources for Magnets

The world's dependence on rare earth magnets has been a topic of concern for several years, with most of the global supply coming from China. This has led to a search for alternative sources to reduce reliance on a single country. One possible solution is to explore other countries with significant rare earth reserves, such as the United States, Australia, and Malaysia. These countries have the potential to become major suppliers of rare earth magnets, providing a more diversified and stable supply chain.

Recycling is another alternative source for rare earth magnets. This involves recovering rare earth elements from scrap materials, such as old electronics and mining waste. Recycling can help reduce waste, conserve natural resources, and decrease the demand for primary production. However, the process of recycling rare earth elements is complex and expensive, making it a challenging alternative.

The challenges and feasibility of these alternatives for Indian automakers are significant. Indian automakers rely heavily on rare earth magnets for the production of electric vehicles and other automotive components. The use of alternative sources, such as recycling or other countries, will require significant investments in research and development, infrastructure, and supply chain management.

- High costs: The cost of recycling rare earth elements is high, making it less competitive than primary production.

- Lack of infrastructure: India lacks the infrastructure and technology to support large-scale recycling of rare earth elements.

- Quality concerns: The quality of recycled rare earth elements can be inconsistent, which may affect the performance and reliability of automotive components.

Despite these challenges, Indian automakers are exploring alternative sources for rare earth magnets. Some companies are investing in research and development to improve the efficiency and cost-effectiveness of recycling, while others are partnering with foreign suppliers to diversify their supply chain.

In conclusion, alternative sources for rare earth magnets, such as other countries or recycling, can help reduce India's dependence on a single supplier and provide a more stable and diversified supply chain. However, the challenges and feasibility of these alternatives must be carefully considered, and significant investments in research and development, infrastructure, and supply chain management will be required to make them viable.

Future Outlook and Mitigation Strategies

The Indian automotive industry is one of the largest and most rapidly growing sectors in the country, with a significant contribution to the nation's GDP. However, the recent magnet freeze has raised concerns about the future of the industry. In the long term, the magnet freeze could lead to a shortage of essential components, resulting in production delays and increased costs for automakers.

The potential long-term effects of the magnet freeze on the Indian automotive industry are multifaceted. The industry may experience a decline in sales and revenue, as well as a loss of market share to international competitors. Furthermore, the magnet freeze could lead to a shortage of skilled workers, as companies may be forced to downsize or restructure their operations.

To mitigate these risks, Indian automakers can consider the following strategies:

- Diversifying suppliers to reduce dependence on a single source of components

- Investing in research and development to improve manufacturing processes and reduce reliance on rare earth magnets

- Developing strategic partnerships with international companies to access new technologies and markets

- Implementing flexible production planning and inventory management systems to minimize the impact of supply chain disruptions

Investing in research and development is a crucial strategy for Indian automakers to mitigate the risks associated with the magnet freeze. By developing new technologies and manufacturing processes, companies can reduce their reliance on rare earth magnets and improve their overall efficiency and competitiveness. Additionally, investing in R&D can help Indian automakers to stay ahead of the curve and capitalize on emerging trends and opportunities in the industry.

Diversifying suppliers is another key strategy for Indian automakers to mitigate the risks associated with the magnet freeze. By sourcing components from a range of suppliers, companies can reduce their dependence on a single source and minimize the impact of supply chain disruptions. This can involve identifying new suppliers, developing strategic partnerships, and implementing robust supplier management systems to ensure the quality and reliability of components.

Overall, the future outlook for the Indian automotive industry is uncertain, and the magnet freeze has highlighted the need for companies to be proactive and adaptable in the face of changing market conditions. By implementing effective mitigation strategies, Indian automakers can minimize the risks associated with the magnet freeze and capitalize on emerging opportunities in the industry.

Frequently Asked Questions (FAQ)

What are rare earth magnets and why are they crucial for the automotive industry?

Rare earth magnets are a type of permanent magnet made from rare earth elements, which are a group of 17 elements with unique properties. These elements include neodymium, dysprosium, and praseodymium, among others. Rare earth magnets are known for their exceptional magnetic properties, which make them essential for many industrial applications.

One of the primary reasons rare earth magnets are crucial is their ability to produce a strong magnetic field while maintaining a relatively small size and lightweight design. This makes them ideal for use in a wide range of automotive applications, including electric motors and generators. In electric vehicles, rare earth magnets are used in the motors that propel the vehicle, as well as in the generators that capture kinetic energy and convert it back into electrical energy.

The use of rare earth magnets in the automotive industry can be seen in several key applications, including:

- Electric motors: Rare earth magnets are used in the production of electric motors, which are used to propel electric and hybrid vehicles.

- Generators: Rare earth magnets are used in generators, which capture kinetic energy and convert it back into electrical energy.

- Sensors and actuators: Rare earth magnets are used in various sensors and actuators, such as those used in anti-lock braking systems and traction control systems.

- Starters and alternators: Rare earth magnets are used in starters and alternators, which are used to start and charge the vehicle's battery.

The unique properties of rare earth magnets make them essential for the automotive industry. They offer high magnetic strength, high resistance to demagnetization, and a relatively small size, making them ideal for use in a wide range of applications. As the demand for electric and hybrid vehicles continues to grow, the demand for rare earth magnets is also expected to increase, highlighting the importance of these materials for the future of the automotive industry.

In addition to their use in electric and hybrid vehicles, rare earth magnets are also used in a wide range of other automotive applications, including traditional internal combustion engine vehicles. They are used in various systems, such as the fuel pump, oil pump, and water pump, among others. The use of rare earth magnets in these applications helps to improve efficiency, reduce size and weight, and increase overall performance.

Overall, rare earth magnets play a critical role in the automotive industry, and their unique properties make them essential for many applications. As the industry continues to evolve and move towards more electric and hybrid vehicles, the demand for rare earth magnets is expected to continue to grow, highlighting the importance of these materials for the future of the automotive industry.

How long is the China magnet freeze expected to last?

The China magnet freeze has been a significant concern for industries relying on rare earth magnets. This freeze has resulted in a shortage of these crucial components, causing disruptions to production and supply chains. The duration of the freeze is uncertain, but it is likely to continue until China's export restrictions are lifted or alternative sources become readily available.

Several factors contribute to the uncertainty surrounding the freeze's duration. China's export policies and restrictions on rare earth magnets can change rapidly, making it challenging to predict when the freeze will end. Additionally, the development of alternative sources, such as recycling or new mining operations, can take time and may not be able to meet the current demand immediately.

Some of the key factors that will influence the duration of the freeze include:

- China's export policies and restrictions on rare earth magnets

- Development of alternative sources, such as recycling or new mining operations

- Global demand for rare earth magnets and the ability of alternative sources to meet this demand

- Technological advancements that could reduce reliance on rare earth magnets

As the situation continues to evolve, industries relying on rare earth magnets must adapt and explore alternative solutions. This may involve diversifying their supply chains, investing in research and development to reduce reliance on rare earth magnets, or exploring new technologies that can mitigate the impact of the freeze. By taking proactive steps, companies can minimize the effects of the freeze and position themselves for success when the market stabilizes.

Can Indian automakers find alternative sources for rare earth magnets?

Indian automakers are heavily reliant on rare earth magnets, which are crucial components in the production of electric vehicles and other automotive systems. The majority of these magnets are currently sourced from China, which has raised concerns about supply chain security and trade dependencies. However, Indian companies can explore alternative sources to reduce their dependence on Chinese imports.

One option for Indian automakers is to import rare earth magnets from other countries, such as the United States, Australia, or Japan. These countries have significant rare earth reserves and are increasing their production capacities.

- The United States has several rare earth mining projects underway, which could provide a new source of supply for Indian companies.

- Australia is also emerging as a significant player in the rare earth market, with several mining projects and processing facilities being developed.

- Japan has been actively promoting the development of its rare earth industry, and could potentially become a significant supplier to Indian automakers.

However, importing from these countries may come with its own set of challenges, including higher costs, logistical complexities, and potential trade barriers.

Another option for Indian companies is to invest in recycling technologies that can recover rare earth magnets from scrap materials. This approach can help reduce waste, conserve natural resources, and provide a secondary source of supply.

- Recycling can also help reduce the environmental impacts associated with primary production, such as mining and processing.

- Several companies are already developing recycling technologies for rare earth magnets, which could provide new opportunities for Indian automakers.

- However, recycling technologies are still in the early stages of development, and more research and investment are needed to make them commercially viable.

Investing in domestic production is another alternative for Indian companies. This approach can help reduce reliance on imports, create new jobs, and stimulate economic growth.

Indian companies can invest in exploring and developing domestic rare earth reserves, which are estimated to be significant.

- Several Indian companies are already investing in rare earth mining and processing projects, which could provide a new source of supply for the automotive industry.

- However, developing domestic production capacities will require significant investment, technological expertise, and regulatory support.

- Indian companies will also need to navigate complex environmental and social issues associated with mining and processing rare earths.

Overall, while there are alternative sources available for Indian automakers, each option comes with its own set of challenges and limitations. Indian companies will need to carefully evaluate these options and develop strategies to mitigate the risks and capitalize on the opportunities.